News + Trends

3-in-1: The Rudy Project glasses are designed to serve as sports, sunglasses and office glasses

by Siri Schubert

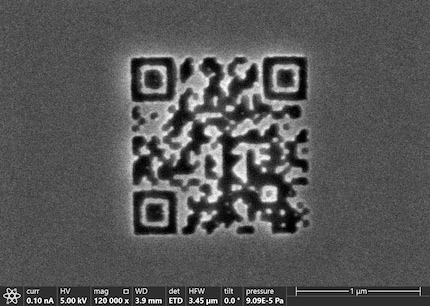

A team from Vienna University of Technology and the Munich-based start-up Cerabyte have developed a QR code that is completely invisible to the naked eye. Nevertheless, it can be read reliably.

Imagine holding an object in your hand that is smaller than most of the bacteria in your body and yet it still contains complete, readable information. This is exactly what scientists at the Vienna University of Technology have achieved together with the startup Cerabyte. Their QR code measures just 1.98 square micrometres, making it officially the smallest in the world. Guinness World Records has verified and recognised the record.

The new code beats the previous record, which was 5.38 square micrometres, by 63 per cent. It is now only 37 per cent of the size of its predecessor.

The centrepiece of the technology is an unusual material: ceramic thin films of the kind used to coat high-performance tools. The researchers milled the QR code into this wafer-thin layer of chromium nitride, which was applied to a glass pane, using focussed ion beams.

The result is a code consisting of 29 × 29 modules in which the individual pixels are only 49 nanometres in size. By comparison, the wavelength of visible light is around ten times larger. No optical microscope in the world could make this code visible, let alone the naked eye.

It is only under an electron microscope that we can see what the scientists have achieved.

Making tiny structures is no longer a speciality in modern research. The real breakthrough lies elsewhere. The decisive difference to earlier experiments with atomic structures is that individual atoms can diffuse. They move to other places, gaps are filled and the stored information is lost. The ceramic layer, on the other hand, remains stable. The code can be read not just once, but repeatedly and reliably.

There is more than just sporting ambition behind the record. TU Wien and Cerabyte have been working together for some time on a new technology for long-term archiving: writing data into coated glass discs. The vision behind this is ambitious and urgently needed in view of the increasing amount of global data.

Conventional data storage devices, whether magnetic or electrical, often have a limited lifespan of just a few years. They require constant power, active cooling and regular data integrity checks to ensure that the information is not lost. Ceramic data storage devices, on the other hand, require neither electricity nor active cooling and the ceramic layer itself is expected to last for many hundreds of years. In the best case scenario, according to the researchers, information could even last for thousands of years.

The potential storage density of the method is impressive: more than two terabytes of data could be stored on the surface of an A4 page. That's the equivalent of thousands of films in high resolution.

Cerabyte currently uses much larger structures in its laboratory. Currently, a disc with an edge length of just under ten centimetres can hold around three gigabytes of data. However, the miniaturisation demonstrated by the new world record shows where the journey could take us.

We now want to use other materials, increase the writing speed and develop scalable manufacturing processes so that ceramic data storage devices can be used not only in the laboratory but also in industry.

At the same time, the team is researching how more complex data structures - far beyond simple QR codes - can be written robustly, quickly and energy-efficiently in ceramic thin films and read reliably. The researchers are explicitly talking about a path to a more climate-friendly data future in which information can be stored permanently and with minimal energy consumption.

My interests are varied, I just like to enjoy life. Always on the lookout for news about darts, gaming, films and series.

From the latest iPhone to the return of 80s fashion. The editorial team will help you make sense of it all.

Show all

News + Trends

by Siri Schubert

News + Trends

by Siri Schubert

News + Trends

by Lorenz Keller